Ceraluminum: Understanding the Aluminum-Ceramic Material

Published on

January 11, 2025

Ceramics

Key Highlights

Ceraluminum is a cutting-edge material merging the strength of aluminum with the scratch resistance of ceramic.

This innovative material boasts a unique tactile experience, offering a warm, stony feel unlike traditional metal or ceramic finishes.

Being 100% recyclable, the innovative material presents a sustainable choice for electronics manufacturing.

Applications span across industries, from sleek laptop exteriors in consumer electronics to high-performance components in aerospace and automotive engineering.

The ceraluminium manufacturing process is environmentally sound, utilizing water and electricity rather than harsh chemicals.

Introduction

In material science, researchers continuously seek materials that are stronger, lighter, and more durable. Plasma ceramic aluminum represents an innovative ceramic material that merges the robust characteristics of aluminum with the resilience of ceramics. Created through a unique oxidation process, this composite material offers a combination of lightweight design and exceptional durability. ASUS recently pioneered the newest version of this new composite material and calls it Ceraluminum.

The Essence of Ceraluminum

Ceraluminum is more than just a coating. It changes the aluminum itself. By using a special ceramization process, a layer forms from the aluminum surface. This creates a strong bond that won’t chip or peel. This method, using ceramics innovation, changes the aluminum's structure. The result is a material that looks good and is very durable.

This unique method in material science leads to a surface that resists scratches and fingerprints. It also has a nice warm feel to touch. Ceraluminum shows the exciting possibilities in material science, bringing together good design and strong function.

Defining Ceraluminum: A Composite Material

Ceraluminum is a composite material that mixes the best qualities of aluminum and ceramic. This combination creates a material that goes beyond what each part can do on its own. It opens up new options in design and engineering. The ceraluminium material is lightweight and can be easily shaped into detailed designs. This is especially useful in areas where keeping weight down is important without losing strength.

Also, the properties of ceramic give ceraluminium material great hardness and scratch resistance. This means it is very tough against wear and tear. It helps products last longer and keeps them looking good.

The Unique Properties of Aluminum-Ceramic Composites

Aluminum-ceramic composites stand out from regular materials. They have special properties because of the combination of aluminum and ceramic. This mix makes them lightweight, strong, and good-looking.

A key feature is its great durability. Unlike other coatings that might scratch or peel, the ceramic layer in Ceraluminum is part of the material. This means it keeps its nice finish and stands up to everyday use.

Here are some other important qualities of Ceraluminum:

Lightweight, even though it is strong. This makes it perfect for cases where weight matters.

The ceramic layer helps prevent corrosion, which makes the material last longer, even in tough conditions.

It lets heat escape well, so it works great for electronics and other heat-sensitive uses.

Applications and Innovations

The special mix of Ceraluminum’s traits allows for many uses in different industries. Its rise marks a big change in material science. It gives manufacturers a flexible solution to make products that look good and are very strong.

Ceraluminum is quickly becoming the go-to material in fields like electronics, cars, and aerospace. This is because it improves both appearance and function. As research continues, we can expect to see even more exciting uses of this great material in the future.

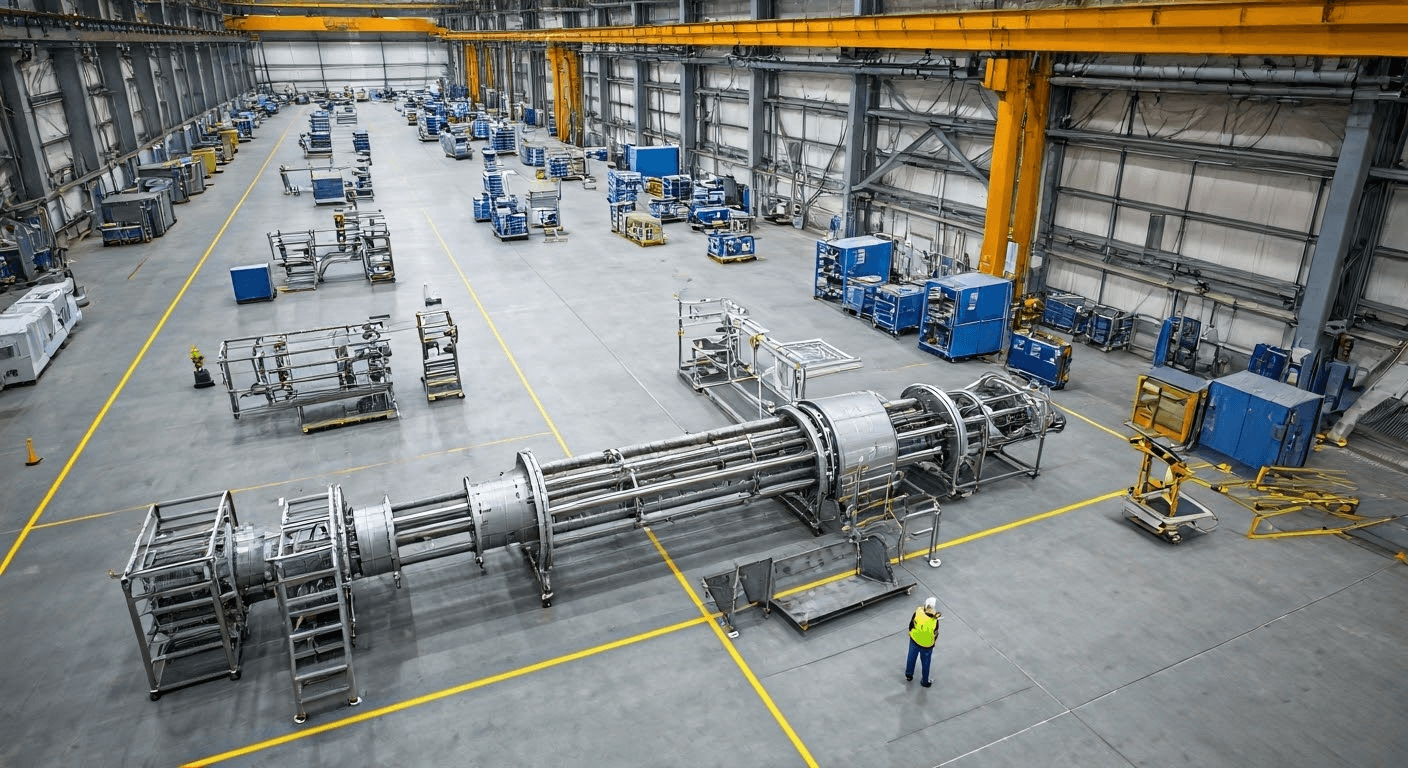

Aerospace and Automotive: Increasing Durability with Ceraluminum

The aerospace and automotive industries are always looking for materials that are light and perform well. Ceraluminum stands out as a great option for many uses in these tough fields. The way we make ceraluminum has improved enough to create parts that meet the high standards of these industries. This material can handle high heat, resist rust, and reduce vibrations. Because of these qualities, it is perfect for engine parts, exhaust systems, and structural parts.

Also, being lightweight helps ceraluminum improve fuel efficiency in vehicles and aircraft. This leads to a lower impact on the environment. As the need for lighter and more efficient vehicles and aircraft grows, ceraluminum will have an important role in the future of these industries.

Consumer Electronics: The Role of Ceraluminum in Modern Gadgets

Ceraluminum has found a natural home in the world of consumer electronics due to its unique properties. Its ability to withstand heat and provide strength makes it an ideal choice for electronic devices such as smartphones, tablets, and laptops. The use of ceraluminum in electronics ensures that these devices are not only durable but also aesthetically pleasing.

Additionally, the lightweight nature of ceraluminum contributes to making electronic gadgets more portable and user-friendly. As electronics, where durability, aesthetics, and lightweight designs are highly sought after. Its ability to withstand scratches and fingerprints, coupled with its appealing tactile qualities, makes it a perfect fit for the exteriors of laptops, smartphones, and other gadgets.

The inherent strength of the ceralumium coating ensures that these devices can withstand the rigors of daily use, maintaining their pristine appearance for an extended period. This aligns perfectly with the consumer demand for durable and stylish electronics that can keep up with their dynamic lifestyle.

The Manufacturing Process

The making of Ceraluminum shows how new ways of manufacturing are changing the industry. Unlike older coating methods that use strong chemicals, producing Ceraluminum is good for the environment. It starts by putting aluminum in a special bath filled with clean water and minerals. Then, an electric current goes through the bath, causing a reaction that helps form a ceramic layer right on the aluminum.

This process not only creates a strong and permanent link between the aluminum and ceramic but also removes harmful chemicals and cuts down on waste. Because of this, Ceraluminum is a good choice for a wide range of uses.

From Raw Materials to Finished Product: How Ceraluminum is Made

Ceraluminum manufacturing is an exciting process. It changes raw aluminum into a strong and good-looking material. The process starts with choosing high-quality aluminum for the final product.

Next, the ceraluminum goes through a special electrochemical process. In this step, the aluminum is put into a bath with a carefully mixed solution of minerals and water. An electric current runs through this bath. This causes a chemical reaction that forms a ceramic layer on the surface of the aluminum.

This ceramic layer is more than just a coating. It becomes a key part of the ceraluminum material. This means it sticks well and will not chip or peel. The end result is a material that has the lightness and flexibility of aluminum but is also hard and scratch-resistant because of the ceramic.

Innovations in Manufacturing Techniques for Better Efficiency

The search for better and more efficient manufacturing methods is always happening in material science. Ceraluminum shows this commitment to innovation. Researchers and manufacturers are always looking for ways to make the production process better for efficiency and sustainability. One key area is reducing how much energy is used in the ceramization process. Scientists are adjusting the electrochemical parameters and looking for other energy sources to make ceraluminum production more eco-friendly.

Additionally, research is ongoing to create new mixes and types of ceraluminum. This aims to change its properties for specific uses. These new developments in ceramics can open the door to new uses for ceraluminum, resulting in even more creative and efficient products.

Conclusion

In conclusion, learning about the science of Ceraluminum can lead to new uses in aerospace, cars, and electronics. Its special qualities and easy manufacturing make this aluminum-ceramic blend strong and useful. Discovering Ceraluminum can help you see the future of materials. If you want to learn more about advanced materials, watch for more insights and findings in our future blogs.

Frequently Asked Questions

What Sets Ceraluminum Apart from Other Materials?

Ceraluminum stands out because of its special ceramization process. This process changes the basic aluminum into a strong ceraluminium material. It does more than just add a surface coating. This method gives it great durability and a distinct feel.

Are there any limitations or drawbacks to using Ceraluminum in manufacturing processes?

The ceramization process makes the ceraluminium material stronger. But it can also make repairs, like welding or reshaping, a bit more difficult. Still, its great durability usually makes this issue less important.

What are some common applications of Ceraluminum in various industries?

Ceraluminum manufacturing serves many industries. It is very strong, which makes it perfect for laptop casings, parts in aerospace, and even automotive components. This shows how versatile this ceramics innovation is.